FULL AND PLANNED MAINTENACE

The A.J. Gates Company offers a wide range of services to handle your material handling fleet. Our factory trained technicians can handle all your maintenance and repair needs. Our Preventative Maintenance (PM) programs help ensure your equipment is productive and provides maximum up-time.

We also offer Full Maintenance programs on new equipment which allows you to carefully budget your maintenance expenses. If you purchase new equipment through us, we can tailor a service agreement for the life of the equipment. If a unit is down, 24-Hour service is available as needed.

Electric Forklift Planned Maintenance

- Batteries & Cables

- Drive Unit

- Mast Assembly

- Contacting Panel

- Electric System

- Pumps & Motors

- Brakes

- Power Contactors

- Hydraulic System

- Total Operational Check & Test Drive

LP Forklift

Planned Maintenance

Included in our gas forklift planned maintenance program:

- Engine

- Hydraulics

- Drive Units

- Battery

- Steering

- Mast

- Electric System

- Total Operational Check & Test Drive

Each unit PM’d receives a sticker with the date of the PM and a listing of the service performed.

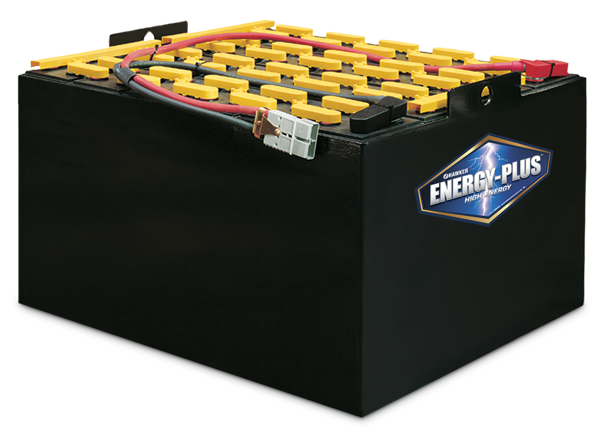

Battery Planned Maintenance

Included in our Battery planned maintenance program:

- Inspect cables and connectors

- Water all cells as necessary

- Run specific gravity on all cells

- Measure cell voltage at rest and under load

- Clean and neutralize corrosion

- Provide detailed written condition report

- Review for safe operation and advise

- Replace faulty contact and connectors*

- Replace missing or damaged vent caps*

- Replacing missing intercell shrouds*

- Advise of proper battery charging procedures in writing

*parts not included

Charger Planned Maintenance

Included in our Charger planned maintenance program:

- Inspect cables and connectors

- Inspect charger sheet metal and cover

- Air blow and clean inside of charger

- Inspect supply circuit

- Verify proper grounding

- Inspect and test internal components and assemblies

- Test and calibrate control unit

- Measure AC amp draws, primary and secondary

- Replace faulty contact and connectors**

- Verify AC amp draws, primary and secondary

- Check wire tie output cables

- Measure DC amps and voltage on charge

- Provide detailed written condition report

- Review for safe operation and advise

**parts not included

Dock Planned Maintenance

Included in our Dock planned maintenance program:

Inspection of:

- Batteries and cables

- Lubrication

- Rollers

- Front and rear hinges

- Pit clean out

- Electric system

- Pumps and motors

- Platform

- Hydraulics

- Cylinders

- Switches

- Hydraulic system